Transitioning to your first aircraft that has ice protection equipment beyond a heated pitot tube is a big step for a pilot. Having a full complement of ice protection usually gives pilots warm fuzzy feelings about being able to complete more trips and handle any ice related problems that arise.

Unfortunately, the current regulations and guidance addressing icing can be just as complex as dealing with the nuances of in-flight icing encounters.

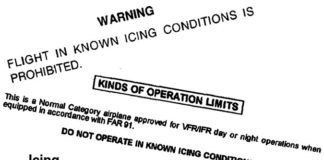

Case in point is the FAA’s recently proposed Airworthiness Directive for 300 and 400 series twin Cessnas produced in the early 1970s and before (Federal Register Docket FAA-2011-0562). The AD would prohibit all covered aircraft from flight into icing conditions because these aircraft were not required to demonstrate adequate ice protection performance when produced.

Performance wasn’t demonstrated because no certification basis existed under 14 CFR Part 23 when they were built.

And that’s the problem. Certification standards for flight into known icing (FIKI) have changed drastically over the years, as has the very definition of what even constitutes icing conditions, and it’s always difficult to hit a moving target. Let’s get to the bottom of what it takes to fly in ice in the current regulatory environment.

Ice Protection Certification

If you fly a relatively new aircraft that is FIKI certified, you should have some confidence in knowing that modern icing certification is a rigorous process which involves demonstrating safe flight in specific icing conditions, known in the regs as Appendix C Icing Conditions. However, it wasn’t always this way. This is where much of the “is it?” or “isn’t it?” confusion arises for pilots flying many older aircraft.

It would be great if every aircraft flying today adhered to the same type certification standards, but that’s not the case by a long shot. Every individual type was required to comply with the standards in place on the date of its certification by the FAA. That certification basis is listed in the aircraft’s Type Certificate Data Sheet (TCDS). This gives you the key to determining the ice protection standards that were required for certification.

Prior to 1974, there effectively weren’t any FAA standards for general aviation icing certification. During this period, aircraft were not specifically allowed or disallowed from flight into icing conditions by the FAA, and any published limitations were made by the manufacturer. In 1974, certification standards were added for general aviation aircraft that parallel transport category ice certification. See the sidebar about the evolution of FAA ice certification.

For many older ice-flying aircraft, there have been thousands of hours flown in real-world icing conditions, and the word on the street from pilot groups, while probably not as rigorous as current FAA certification standards, is certainly more thorough than what most test flights can accomplish. Therefore, it is beneficial to investigate the certification standards for your aircraft as a way of predicting future FAA interest in the icing capabilities of your aircraft type, such as with the proposed twin Cessna AD.

Does It Carry Ice Well?

One of the first questions a pilot will ask when transitioning to an aircraft with ice protection is about how well it carries ice. This is a reasonable and insightful question to ask. Every aircraft carries ice differently, with the variability coming from the wing shape, type of ice protection being used, type of ice encountered and a variety of other factors. In my experience one of the biggest factors is the power to weight ratio. After all, given enough horsepower you can make an ice-laden barn fly.

Back in my freight dog days, I primarily flew the Cessna Caravan, a great flying airplane with a bit of a bad reputation (partially deserved, partially undeserved) when it came to ice. The Caravan certainly had ramp presence. It was big. Even with that 675 shp engine hanging off the nose, it was actually underpowered. That engine had to pull an aircraft that maxed out at 8,550lbs with the cargo pod. This yields a power loading ratio of 12.67 pounds per horsepower. Look at the included table of common aircraft for comparison.

An aircraft’s ability to climb is directly related to power in excess of that required to maintain level flight and is of critical importance when dealing with an icing encounter. The Caravan was a deceptively easy plane to fly, but its lack of excess power is the root cause of its icing reputation. The Caravan could certainly carry a load of ice, but because of the lack of available power to climb, the pilot simply wasn’t permitted as much time to form a plan to deal with an icing encounter as might have been allowed in another aircraft type.

Keep in mind that the power being considered here is the available horsepower, which decreases with altitude for normally aspirated aircraft.

Additionally, remember that ice is heavy, and that the bigger the physical size of your aircraft, the more unprotected surfaces will become contaminated and the quicker weight will build due to ice accumulation. So if your aircraft is already at its maximum weight (in the absence of an ice weight limitation), picking up ice could mean you have become over gross weight while aerodynamically compromised. That’s not a good combination.

Knowing Conditions

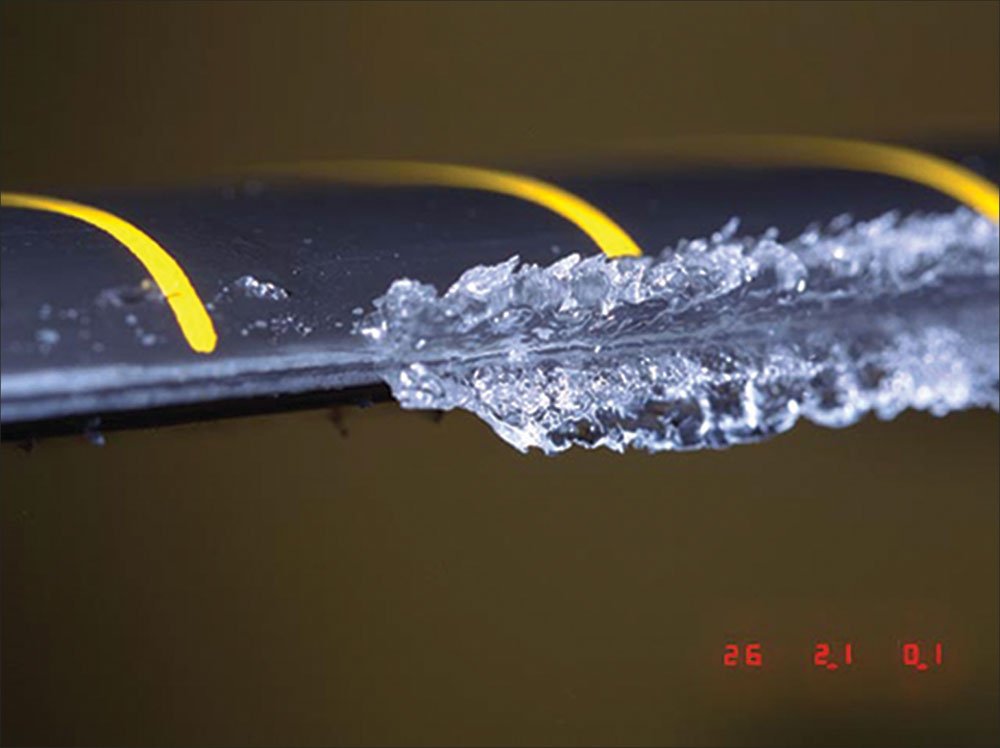

The current standards for ice certification for both normal and transport category aircraft are limited to the scientifically described icing conditions documented in Appendix C of FAR Part 25. A challenge for pilots flying aircraft certified under that section is being able to correlate those scientific standards with what they’re seeing outside and identifying conditions that exceed those standards. Specifically, supercooled large droplet ice (SLD), freezing rain and freezing drizzle, all of which cause ice accumulations aft of protected surfaces, are outside of the standards for any aircraft.

For a long time, “known icing conditions” were only defined by case law and legal interpretations. In 2006 an FAA interpretation attempted to define it as temperatures at or below freezing in visible moisture, which effectively meant any clouds in the winter. In 2009 they backpedaled into a surprisingly common-sense definition that known icing conditions exist when a reasonable and prudent pilot would know of them based on all the weather information available at that time.

Now the responsibility is on the pilot to become educated into understanding what causes ice, self-certify that a proposed flight will not exceed his aircraft’s icing capabilities and make contingency plans for unforecast icing encounters. For aircraft lacking a FIKI certification, that means steering clear of all forecast ice. For known-ice aircraft, that means steering clear of all forecast ice that exceeds limitations on the aircraft type, or common sense.

The graphical weather products that are available today make planning to avoid ice much easier than even a few years ago. AIRMETs and SIGMETs, combined with freezing level graphics and pilot reports, supplemented with the Current/Forecast Icing Potential graphics, give pilots many valuable tools to use. Part of the challenge of forecasting ice is its fickle nature—as air masses evolve, icing conditions in an area can change significantly over a short period of time. Therefore, on an IFR winter flight that’s expected to be clear of ice, always pay attention to conditions that don’t seem to be supporting your pre-flight analysis.

Developing a Known-Ice Pilot

FAA certification of an aircraft for flight in icing conditions encourages the already common misconception that it’s safe to fly in icing conditions and that pilots can relax. This is an important point that can’t be overstressed. Just because an aircraft is granted known icing certification by the FAA, even using today’s more stringent standards, does not constitute an authorization to fly in any conditions. In fact, for most aircraft and GA aircraft in particular, FIKI certification should be viewed by the pilot as merely an ability to transit brief icing encounters, not to fly through ice for hours.

Like so much in aviation, we know a lot more about ice today than we did a few years back, but we’re still a long way from knowing all there is to know. Having a defined standard for ice protection is certainly useful, but it is not sufficient. We’re always reading about aircraft that have met all the modern Part 25, Appendix C, certification standards finding out exactly how much ice is too much for their aircraft type, and paying dearly for the discovery. Unfortunately, Mother Nature doesn’t always adhere to the Appendix C definition of ice.

Consider one of the findings made by the NTSB after the 1994 ATR-72 crash in Roselawn, Indiana:

The 14 CFR Part 25, Appendix C, envelope is limited and does not include conditions of freezing drizzle or freezing rain; thus, the current process by which aircraft are certified using the Appendix C icing envelope is inadequate and does not require manufacturers to sufficiently demonstrate the airplane’s capabilities in all the possible icing conditions that can, and do, occur in nature.

I suspect we’ll never be able to demonstrate capabilities in all possible icing conditions that Mother Nature can throw at us. Therefore, safety in icing conditions should be primarily a factor of pilot education, respect for the pilot’s and the aircraft’s limitations and the rarest and most valuable asset there is: common sense.

Ice Certification History

Part 4 of the Civil Air Regulations (CAR) was the only certification standard before 1945, and it applied to all aircraft, whether a J-3 or a DC-3. Its only ice protection standards addressed deflating wing boots, if any. In 1945, CAR Part 3 was created for certification of small (< 12,500 pound) aircraft. CAR Part 4 was revised for large and transport category aircraft. No changes were made to ice protection standards at that time.

Ice protection standards in CAR Part 4 were revised in 1953, 1955, and 1957, and became today’s Appendix C certification standards. Still no ice protection standards were added to CAR Part 3. In 1965 when the CAA became the FAA, CAR Part 3 became FAR Part 23, and CAR Part 4 became FAR Part 25. FAR Part 23.1419 only carried the original requirement to deflate de-ice boots if installed.

In 1973, Amendment 23-14 rewrote the ice protection standards to more closely align general aviation with transport category aircraft. General aviation aircraft now had to demonstrate that “the airplane is capable of operating safely in continuous maximum and intermittent maximum icing conditions as described in Appendix C of Part 25.” A similar requirement existed for CAR Part 4/FAR Part 25 aircraft since 1955. Note that aircraft type certificated before this amendment were unaffected as long as the original type certificate remained in effect.

Amendment 23-43, the most recent change in 1993, further revised FAR Part 23 ice certification standards by rewording and clarifying existing requirements. It also expanded certain areas to more closely match large and transport category requirements. —LS

Lee Smith, ATP/CFII, has flown cargo, charter and corporate operations, but now flies a desk as an aviation consultant in northern Virginia.