Some aviators are perfectly happy flying what’s available. Others of us yearn for ever better-equipped aircraft. Somewhere in the middle is taking what you’ve got, and modifying it to better suit your mission, or even just your wishes. There are many avenues by which you can modify your aircraft. Let’s explore the most common. (Note: What follows is not intended to be a checklist or cookbook. Instead, the goal is to give you a good understanding of the complex requirements to approve a proposed modification.)

Has It Been Done?

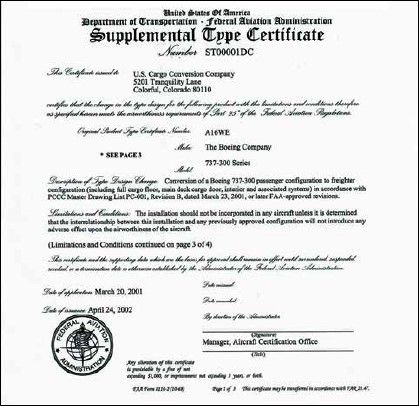

The first step in your journey should be to check to see if anyone has already made the modification you want. You could Google the mod or go to the FAA’s Regulatory and Guidance Library at https://rgl.faa.gov/. For example, if you have a Cessna 340 and want to improve the turbo intercooler, you can check the database to see if the modification already exists. In this case, STC SA4158NM seems to fit the bill. The Supplemental Type Certificate (STC) owner is American Aviation, Inc. in Hayden Lake, ID.

If you want to make a major change that has not been done previously, there are a couple of ways to proceed. First, there is the possibility of a Field Approval from the Flight Standards District Office (FSDO). Second, you can also apply for an STC through your local FAA Aircraft Certification Office (ACO).

Form 337

Field Approvals using a 337 Major Repair and Alteration Form were common a few decades ago. FAA Form 337 was filled out and, along with approved data, was sent to the FSDO for approval. However, in the intervening years, FSDOs have gotten gun shy and refer many requests to the ACO. Today an

FAA Designated Engineering Representative

(DER) is usually required to fill out an FAA Form 8110-3, which is then called out on the 337.

This policy change has been traced to FSDOs approving Lear and Citation cargo conversions. According to reports, the FSDOs issued approvals for Part 23 aircraft cargo conversions, however, the modifications in question were on Part 25 aircraft. The modifications ran afoul of Air Transport cargo compartment requirements. It caused a stir within the FAA and the FSDOs came away chastised and have become quite cautious approving 337s.

The result is that today any original modification, although potentially eligible for a 337 approval, can be an uphill slog to get something the FSDO will, indeed, approve.

On the other hand, most avionics upgrades or retrofits are relatively straightforward. The avionics manufacturer will often get an STC on one aircraft model and then expand that certification through an Approved Model List (AML) listing all the aircraft for which the device is approved. If your aircraft is on the AML, the installer merely submits a 337 to document the change by referencing the original STC

and AML.

Most avionics manufacturers have established AMLs for their products. Even “exotic” equipment like Max-Viz enhanced flight vision systems have a large AML for their STC. Dynon has nearly 600 aircraft on the AML for its SkyView HDX cockpit display system.

STC Process

If a field approval isn’t possible, you’ll need an STC. The STC route is complex but is required for any major modifications. You can apply for the STC yourself, but you should have experience before tackling the project. See the sidebar. If you handle it yourself, you would be the Program Manager like a General Contractor. However, it is costly and time-consuming. You’ll need the expertise of FAA Designated Engineering Representatives (DERs) and Airworthiness Inspectors (DAR), among others. A listing of Designees can be found on the FAA website at https://www.faa.gov/quick_reference/. Scroll down to “Designees….”

You will need to know Advisory Circular AC 21-40A “Guide for Obtaining a Supplemental Type Certificate” inside and out. The FAA and the aviation industry also developed a “Guide to Product Certification.” This guide lays out roles and responsibilities between you and the FAA. It was written from an aircraft manufacturer’s point of view but is still useful and should be reviewed. There is no quicker way to get sidelined than to go into the initial FAA meeting and not know the process.

Jumping In

If you’re brave enough (and sufficiently funded) to proceed, you should discuss the modification with a Maintenance, Repair and Overhaul facility (MRO) that has Field Approval and STC experience to get their impressions.

If you still want to be the Program Manager and have talked to an MRO, you should next discuss it with the FSDO to assess the scope and complexity. They will go over the change relative to 14 CFR 1.1 and Part 43, Appendix A. Don’t get your hopes up that the FSDO can handle it. If it is a new modification, they will probably hand it off to the ACO.

The next step after the FSDO would be to contact the ACO manager at the nearest ACO. The ACOs are in 10 major cities located around the country. The address for each ACO can be found at https://www.faa.gov/aircraft/air_cert/locate_office/aco/.

Requesting a familiarization briefing allows you to describe the project before making a formal application. At this meeting, the FAA will check your knowledge of the STC process, provide guidance, and discuss their current workload. They will likely discuss the project sequencing process, which may delay the initiation of your project, or it could be assigned to another ACO.

If your proposed modification is “new and novel,” they will discuss the process of sending it to Headquarters (Washington, DC) for review. Beyond the design features, the ACO will want to know if this will be a one-time STC or multiple-use on other same-model aircraft. They may ask questions about who will be doing the installation work and the use of designees or delegated organizations (ODA). This familiarization meeting is usually informal but can set the direction for future work.

Application

Before any formal STC work begins and FAA personnel are assigned to the project, you need to submit FAA Form 8110-12, Application for Supplemental Type Certificate. You should send the application to the local ACO along with a cover letter and your certification plan. The certification plan will be the focal point of the first formal meeting. The plan should be comprehensive and sufficiently detailed to allow a good understanding of how you plan to accomplish the requirements for certification, i.e., the certification basis.

Your aircraft was certified to the standards that existed at the time of its original certification. The regulations have likely changed since then. Suppose

you just list the current regulations for the certification basis. In that case you will be required to bring the aircraft up to current requirements—a mistake that could make the project prohibitively expensive. However, the FAA is the final authority on the certification basis and may require you to meet some newer requirements.

A compliance checklist, compiled after the certification basis is agreed upon, is used to show which regulations apply to the project. It also shows how compliance with each regulation will be demonstrated (analysis, structural test, ground test, or flight test). The first time you generate the certification basis and compliance checklist will be eye-opening on how many regulations will apply.

Once the certification plan has been approved and the compliance checklist is completed, an Interim Type Certification Board (TCB) meeting may be requested by either the ACO or yourself. The compliance checklist would be the focal point of this meeting. The TCB meeting establishes consensus among the FAA specialists and yourself that all the applicable regulations have been addressed.

Implementation

Your data submittals must contain enough detail and substantiating data to describe the design of the modification or installation completely, and that the design complies with the applicable airworthiness standards. The type of data that needs to be submitted depends on the actual modification you are making. It will always include installation information, but if it is an airframe modification such as a new winglet, much of the data will be structural load analysis and aircraft performance. If it is a new avionics widget, the data package will usually involve software and hardware design and environmental test information. If it is powerplant related, the data package will primarily be around the engine itself, structural mounting, fire protection, as well as aircraft performance data.

In addition to approving the data for the STC, the FAA also reviews how the alteration will affect aircraft operation and maintenance after the STC is complete. This normally requires the generation of a flight manual supplement (AFMS) and instructions for continued airworthiness (ICA). The ICA is reviewed by a different organization within the FAA but should be generated in conjunction with the STC.

As part of the certification process, the ACO should identify the areas to be conformed for certification. The FAA conformity inspections physically compare the components or modifications to the engineering specifications, drawings, and airworthiness standards. Conformity inspections need to be completed before any official FAA tests are conducted. FAA Form 8120-10, Request for Conformity, is used for this purpose. FAA aviation safety inspectors (manufacturing), FAA-authorized designated manufacturing inspection representatives (DMIR) or manufacturing DARs perform conformity inspections.

After the conformity inspection, testing is required to demonstrate compliance with the applicable regulations. Test results from a component, ground, and flight testing, may be required.

There are companies that specialize in obtaining STC’s for their customers. Companies such as Paragon Transport LLC in Peoria, AZ at www.faa-der.com offer this service. They have DER’s that can cover all of the disciplines, such as structural analysis, system safety, and the others required to get an STC. The advantage of this approach is they interact with the FAA officials every day and have already established a working relationship. You as an individual would normally go to the bottom of the list with a new STC.

Before proceeding you should also discuss it with a Maintenance, Repair and Overhaul facility that specializes in aircraft modifications. Companies such as Yingling Aviation in Wichita, KS, can give you a quote on handling the job from start to finish. In this case, they would be the Program Manager and the STC would be in their name. Understandably they would only be interested in a modification that has broad appeal to other aircraft owners.

Either way, being the Program Manager or contracting it out is not cheap. It’s not as bad as the old joke on how to make a small fortune in aviation…start with a large one, but you should plan on unexpected contingencies, just like in “Love It or List It?”

Getting Close

The end of the effort is in sight when the FAA issues the Type Inspection Authorization (TIA). The TIA details and authorizes the required aircraft conformity and airworthiness inspections and the ground and flight tests necessary to fulfill certification requirements. Only after the examination of the technical data, including the “company” flight test report is complete and the flight test risk management assessment has been performed, will the ACO issue the TIA. FAA Form 8110-1, Type Inspection Authorization is completed by the ACO’s engineering staff for this step.

To conduct developmental flight testing you must ensure that the aircraft is in the experimental category and receives an experimental airworthiness certificate for research and development. It will also be required for FAA flight testing. Flight test cards are prepared for use on both “company” flight tests as well as suggested profiles for the FAA flight testing. You must complete all inspections and tests required by the TIA satisfactorily before the FAA will issue the STC.

Provided the flight testing was satisfactory and all the reports have been reviewed, the ACO will grant final approval of the modification and issue the STC. The complete certification basis will be included on FAA Form 8110-2.1. If the STC was for multiple-use, the information will be made available at https://rgl.faa.gov/. The ICA and Flight Manual Supplement will need to be kept up to date.